Milton Keynes College Takes Off with TecQuipment AF1300 Wind Tunnel

Addressing the Aeronautical Engineering Skills Shortage

In response to the world skills shortage of aeronautical engineers, in 2016 Milton Keynes College began a dedicated Aeronautical Engineering BTEC. This course, headed up by Sean Hainsworth, former RAF Aerospace Engineer, first began as a trial. Following the course’s success, Milton Keynes College has a full cohort of 40 applicants aiming to start in September 2018.

Wind Tunnel in the Syllabus

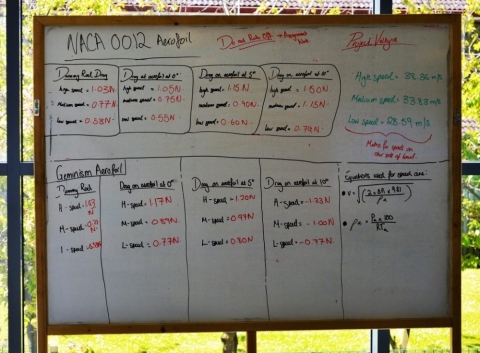

Students are required to complete projects that involve the design, manufacture and test of aerofoils throughout the year. As part of the course, students have a project to design and build three types of aerofoil, testing with three angles in the wind tunnel (0 degrees, 5 degrees and the critical 15 degree stall angle) and then applying three different equations (lift, drag and wind speed).

Pearson BTEC Level 3 Diploma in Aeronautical Engineering

The AF1300 Subsonic Wind Tunnel is used as a standard piece of equipment in specialist aeronautical engineering facilities across the globe. For the Pearson BTEC Level 3 Diploma in Aeronautical Engineering, the equipment utilised for the following learning units:

- Unit 5 Mechanical Principles and Applications

- Unit 48 Theory of Flight

- Unit 68 Principles and Applications of Aircraft Mechanical Science

About the AF1300 Subsonic Wind Tunnel

The AF1300 is a widely used piece of aerospace engineering teaching equipment that allows undergraduate and research students to study the principles of aerodynamics. The compact size reduces space requirements and experiment time compared to full sized wind tunnels, due to the ease of model changeover, of which can be switched with minimal or no supervision. The wind tunnel is available with a range of different models (standard cylinder, NACA standard aerofoils, 3D drag models, flat plate drag models, flat plate boundary layer models with tapings and aircraft models with low and high wing configurations).

TecQuipment

TecQuipment designs, develops, and produces a comprehensive range of products for engineering training. The company is well known as a preeminent provider of technical teaching equipment for schools, colleges, universities, and industrial training centers worldwide.

TecQuipment operates a constant product improvement process to guarantee that the teaching equipment stays ahead of the competition and meets customers’ needs. The product ranges are reviewed and updated, and new products are developed as curricula change. Manufacturing on-site enables the engineering team to work alongside production to guarantee that quality products are designed and produced to give end-users many years of safe, accurate and reliable usage.

Maintaining high quality of all TecQuipment products is crucial. Strict quality control guidelines at each stage of development ensure the products consistently meet very high standards. These systems are robust and designed to withstand long-term, substantial laboratory and classroom use and ensure reliable operation for many years. All TecQuipment products include comprehensive user guides, which provide relevant theory, technical information, and experiments. The comprehensive level of support helps students understand the principles involved in each experiment, enabling them to put theory into practice.

Engineering Educational Equipment

TecQuipment designs, develops, and manufactures a comprehensive range of technical education products and engineering educational equipment for schools, colleges, universities, and industrial training centers worldwide. Products cover disciplines within mechanical, civil, electrical, and structural engineering courses.

TecQuipment’s engineering educational equipment includes high-quality user guides, which provide relevant theory, technical information and experiments. The comprehensive level of support helps students understand the principles of each experiment, enabling them to put theory into practice.