Free and Forced Vibrations

Benchtop apparatus that investigates the free and forced vibrations of a rigid beam with a spring, and a simply supported beam. Demonstrates Rayleigh's approximation and Dunkerley's method.

This product is part of a range that explores free vibrations in simple ‘one degree of freedom’ systems.

This product includes a beam pivoted at one end, with the other end suspended by a coiled spring. You can compare this with the mass-spring system, except the mass moment inertia of the beam replaces the simple mass. This common system appears in machines and vehicle suspensions.

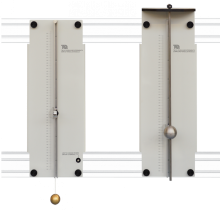

A back panel fixes to the Test Frame. The panel holds a pivot and a non-contacting displacement sensor. The pivot contains high-quality self-aligning bearings that hold the left-hand end of a rigid beam while allowing it the freedom to rotate through a small angle. The sensor measures the oscillations at the right-hand end of the beam with negligible damping while working to guide the movement.

The beam is of a ‘ladder’ type construction with equally spaced ‘rungs’. The rungs provide convenient mounting positions while maintaining a uniformly distributed mass along the beam’s length. TecQuipment includes a set of masses to add to the beam, increasing its inertia. A separate spring bracket above the beam holds a choice of two springs to suspend the beam from any rung along its length. Both the back panel and spring bracket have printed scales. Students use the scale on the back panel to easily position the masses, spring and optional damper along the beam. They use the scale on the spring bracket to show Hooke’s Law and find the spring constant. Students pull the beam gently down and release, allowing it to vibrate. They then find the frequency of oscillation and compare it with that predicted from theory.

The multiple positions along the beam allow students to try their own combinations of experiments, in addition to those suggested. For example, they could try different spring positions or multiple masses.

TecQuipment calibrate the displacement sensor to work with VDAS (mkII) for real-time display and data acquisition of system oscillation waveforms. Students use the software to see the displacement waveform and measure frequency. The software calculates and shows the first two derivatives of displacement - velocity and acceleration.

TecQuipment has specifically designed the TM167 to work with VDAS (mkII). However, the sensor output may be connected to your own data acquisition system or oscilloscope if desired.

Students may fit an optional Damper Kit (TM167a) to test how viscous damping affects the beam oscillations. This simple piston disc and cylinder form a dashpot damper that fits to the Test Frame under the beam. It works with easily found non-toxic fluids (not supplied) for different damping levels. For example, water and vegetable oil will produce light damping, while castor oil produces heavy damping. Students may try their own fluids (provided they are safe and do not damage the equipment) and their own piston discs for project work.

When using the Damper Kit, VDAS can fit its displayed data to under-damped and over-damped viscous damping models.

It introduces students to key scientific terms such as:

Note: You may purchase any number of damper kits to make the change between the various fluids more convenient.

This product fits to the sturdy Test Frame (TM160) for study or demonstration.

Benchtop apparatus that investigates the free and forced vibrations of a rigid beam with a spring, and a simply supported beam. Demonstrates Rayleigh's approximation and Dunkerley's method.

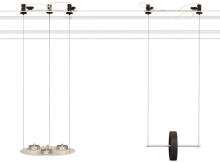

Experiment for studying simple harmonic motion and the factors that affect the period of oscillation of pendulums. Fits on to the Free Vibrations Test Frame.

Experiment for studying simple harmonic motion and the factors that affect the period of oscillation of bifilar and trifilar pendulums. Fits on to the Free Vibrations Test Frame.