Demonstrates the forces, moments and reactions of a rigid beam.

Education Equipment for Teaching Alternative Energy Principles

The alternative range offers teaching equipment for the core principles of different types of alternative energy including solar and wind turbine generated energy.

Pages

-

Item Number:STF5 - Experiment

-

Item Number:STF3 - Experiment

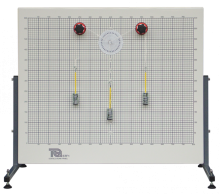

Practical demonstration of the equilibrium of a ladder.

-

Item Number:STS22 - Experiment

TecQuipment's Equilibrium of a Simply Supported Beam (Next Generation Structures) is an experiment to study the characteristics of a simply supported beam. Mounts on the Structures platform and connects to the Structures automatic data acquisition unit and software.

-

Item Number:STF4 - Experiment

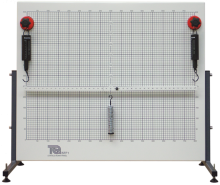

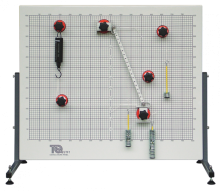

Demonstrates concurrent and non concurrent coplanar forces. Allows students to construct force polygons and understand conditions for equilibrium.

-

Item Number:SM1005 - Experiment

Shows the various modes of buckling (elastic collapse or crippling) of slender compression members.

-

Item Number:STS12 - Experiment

TecQuipment's Euler Buckling of a Column (STS12) is an experiment for the study of buckling of struts and the relationships between length, end fixing conditions and buckling load. Mounts on the Structures platform and connects to the Structures automatic data acquisition unit and software. This is one of the 21 apparatuses available in TQ's Next Generation Structures engineering lab experiments.

-

Item Number:TD1004V - Experiment

Bench-top apparatus to demonstrate the behavior and expansion processes of a perfect gas.

-

Item Number:app

The Experience Controls app is a unique interactive mobile textbook introducing students to control systems fundamentals in an engaging way, through accessible language, real-time dynamic simulations, and self-directed learning. The accompanying instructor resources allow educators to easily implement Experience Controls into any new or existing control systems course.

-

Item Number:PSA25 - Ancillary

A feeder management relay presented in an educational format to enable investigations into the protection and monitoring of overhead lines and underground cables.

-

Item Number:TM162

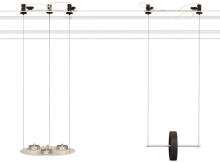

Experiment for studying simple harmonic motion and the factors that affect the period of oscillation of bifilar and trifilar pendulums. Fits on to the Free Vibrations Test Frame.