Heat Transfer Experiment Base Unit

A bench top base unit for demonstrating different methods of heat transfer. Requires at least one of the four optional experiments.

The equipment is self-contained with the control unit housed in an instrument case that forms the base. It comprises the calorimeter, a calorimeter vessel, an outer double-walled water vessel, electric stirrer gear, combined motor control gear, an ignition unit, a digital precision thermometer, and a charging unit with pressure gauges to facilitate the charging of the calorimeter with oxygen.

The particular features of the calorimeter are the method of sealing and the method of ensuring ignition. The body of the calorimeter is screwed into the base and a seal is made with a special rubber joint when the two parts are finger-tight only. No spanners are required and in use, the rubber joint is protected by water so it may be used over and over again. In order to make ignition 100% sure, great care has been devoted to the method of anchoring the ignition wire and maintaining electrical contact, and to the support of the crucible. All these parts are made to a high degree of precision and the results are very satisfactory.

The calorimeter is machined from a solid billet of stainless steel which after completion is tested to a pressure of 310 bar (4500 lb/in²). It meets the Institute of Petroleum Designation IP12/73 Heat of Combustion of Liquid Hydrocarbon Fuels for Calorimeters. The calorimeter vessel and outer vessel wall are fabricated from stainless steel and all parts are made to an extremely high manufacturing standard.

A bench top base unit for demonstrating different methods of heat transfer. Requires at least one of the four optional experiments.

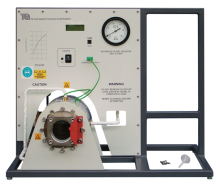

An experimental apparatus to derive the temperature-pressure relationship for saturated steam, and verify the Antoine Equation.

A self-contained mobile module for temperature process control experiments to illustrate the principles of single-loop control and the calibration & tuning of controllers, transmitters, converters and valves. Demonstrates feedback control, ON-OFF control, P/PI/PID control, distance-velocity lag and temperature control. Distributed control available when used with an optional computer control system.