Digital Hydraulic Bench

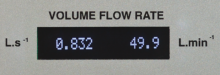

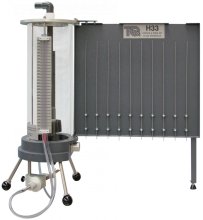

TecQuipment's Digital Hydraulic Bench provides a controlled recirculating water supply and accurate flowmeter for hydraulic and fluid mechanics engineering experiments.

The TecQuipment Vortex Apparatus enables students to produce both free and forced vortices, and measure the vortex water surface profile.

The equipment consists of a transparent vessel on a support frame, which mounts on a TecQuipment hydraulic bench (Gravimetric or Volumetric Hydraulic Benches, H1 or H1D - available separately). It may also work with another suitable clean water supply and drain.

A low-voltage, variable-speed motor rotates the vessel about its vertical axis. A speed-control unit (included), sited away from the main apparatus, controls the speed of rotation.

To produce a forced vortex, students add water to the rotating vessel until it is about half full. A forced vortex forms. After a few minutes, the vortex becomes constant, and students can measure the surface profile using the traverse probe. The traverse probe can move both horizontally and vertically, and both axes have linear scales. Students can also measure the distribution of total head by replacing the traverse probe with a Pitot tube.

To produce a free vortex, students place a smaller, perforated transparent cylinder inside the main vessel. This forms an annulus into which a continuous water supply is directed. When the vessel rotates, water passes through the perforations and spirals slowly inwards to a small hole in the center of the base of the vessel. The surface falls rapidly towards the center and produces an air core. Students measure the surface profile using the traverse probe.

TecQuipment's Digital Hydraulic Bench provides a controlled recirculating water supply and accurate flowmeter for hydraulic and fluid mechanics engineering experiments.

An apparatus to allow students to investigate the friction losses in piping systems. The large open format of the apparatus makes it ideal for students working in small or large groups.

An apparatus to allow a full study of the discharge through an orifice or nozzle mounted vertically or the trajectory profiles of an orifice or nozzle mounted horizontally.