Calibration of a Pressure Gauge

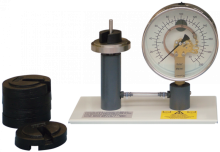

A bench mounting apparatus for calibrating Bourdon type pressure gauges using deadweight techniques.

Manometers and Bourdon gauges are fundamental pressure-measuring devices. They are intrinsic parts of more complex measuring instruments, such as pneumatic comparators and flow indicators. It is important therefore that students fully understand their operation, characteristics, and principles of calibration.

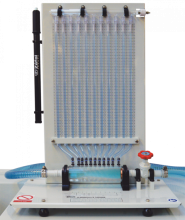

TecQuipment’s Pressure Measurement Bench enables students to fully investigate and compare the operation and characteristics of inclined and U-tube manometers, and Bourdon-type vacuum and pressure gauges. It also includes a separate Bourdon gauge with dead-weight calibration apparatus, enabling clear observation of the Bourdon tube mechanism.

The apparatus consists of two units:

The manometers and gauges unit is a framed structure with a backboard, holding a:

in the measurement devices.

Each gauge and manometer has a delivery point to connect to the syringe using plastic tubing (included). All connections are push-fit, and T-pieces are provided to enable two instruments to be connected to one point. The Bourdon pressure gauge calibration unit consists of a piston, which is free to move vertically, in a close-fitting cylinder. A transparent, flexible hose connects the cylinder to the Bourdon pressure gauge. The gauge and cylinder are mounted on a common flat base.

The internal mechanism of the gauge is clearly visible through the transparent dial. During a test, calibration weights are placed onto the loading platform, which is an integral part of the piston assembly. All air is expelled from the system through a purge hole in the upper part of the cylinder.

The apparatus is manufactured using materials and finishes carefully chosen to give the fullest protection against corrosion.

A bench mounting apparatus for calibrating Bourdon type pressure gauges using deadweight techniques.

An educational Venturi tube that allows students to study the Venturi meter and Bernoulli's Theorem and to make direct comparisons between the results obtained by experimentation and those predicted by theory.

Provides motive power with speed, torque and power measurements for TecQuipment's Modular Fluid Power Range.