Propeller Turbine

Propeller Turbine for use with the MFP101 Centrifugal Pump Module.

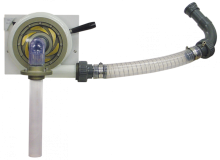

You need the Turbine Dynamometer for tests on the optional turbines. It fits on the Centrifugal Pump Module, near the outlet end of the centrifugal pump. You fit any of the three optional turbines to the Turbine Dynamometer. Each turbine has a brake drum that fits inside the dynamometer.

You connect the outlet of the centrifugal pump to your turbine. As the pump forces water through the turbine, you use a control on the Turbine Dynamometer to adjust a band brake. This loads the turbine. The Turbine Dynamometer and its instrumentation then measures and displays the speed, torque and shaft power available at the dynamometer.

The Turbine Dynamometer instrumentation fits above the dynamometer, in the iInstrument frame of the Centrifugal Pump Module. It has a socket for connection to TecQuipment’s optional VDAS®.

Propeller Turbine for use with the MFP101 Centrifugal Pump Module.

An educational apparatus to allow students to observe the operation of a Pelton turbine and to determine its performance characteristics.

The Francis Turbine is a reaction turbine. It is the most common turbine in the world, due to its ability to work for a wide range of applications. Its moving part (runner) is a radial impeller.