Balance of Reciprocating Masses

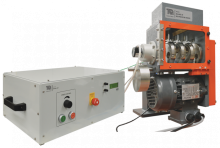

A bench-mounted model four-cylinder engine with control and instrumentation unit that demonstrates the primary and secondary forces and moments when balancing reciprocating masses.

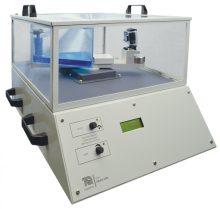

This product allows students to do experiments in balancing a rotating mass system and check their results against accepted theory.

A sturdy base unit holds a test assembly on four flexible mounts. The test assembly includes a balanced steel shaft mounted horizontally on low friction bearings. The equipment includes a set of four rotating masses (balance blocks). The balance blocks fix in any horizontal position and relative angle on the shaft. Each block contains a different (and removable) circular insert, allowing students to create four blocks of different mass and moment. Without the inserts, the blocks become four identical masses for simple balancing tests.

Students fit an extension shaft and pulley (supplied) to the end of the balance shaft. They then add weights (supplied) to a cord wound around the pulley to measure accurately the moment of each balance block.

The test assembly includes a protractor at the end of the shaft and a linear scale with a slider under the shaft. These allow accurate measurement of balance block angles and horizontal positions.

An electric motor and belt turns the shaft to test for dynamic balancing. The flexible mounts allow the assembly to vibrate, showing imbalance during dynamic balancing tests. Students remove the belt to check for static balance (the shaft should remain static at any angular position).

A transparent safety dome covers the whole rotating assembly. An interlock shuts off power to the motor when the dome is not fitted.

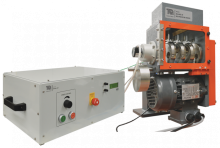

A bench-mounted model four-cylinder engine with control and instrumentation unit that demonstrates the primary and secondary forces and moments when balancing reciprocating masses.

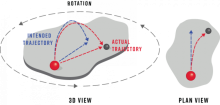

A highly visual demonstration of the Coriolis Force on a jet of water.

A compact, bench-mounted apparatus that demonstrates ‘whirling’ in different horizontal shafts with a variety of fixings (end conditions), loaded and unloaded.