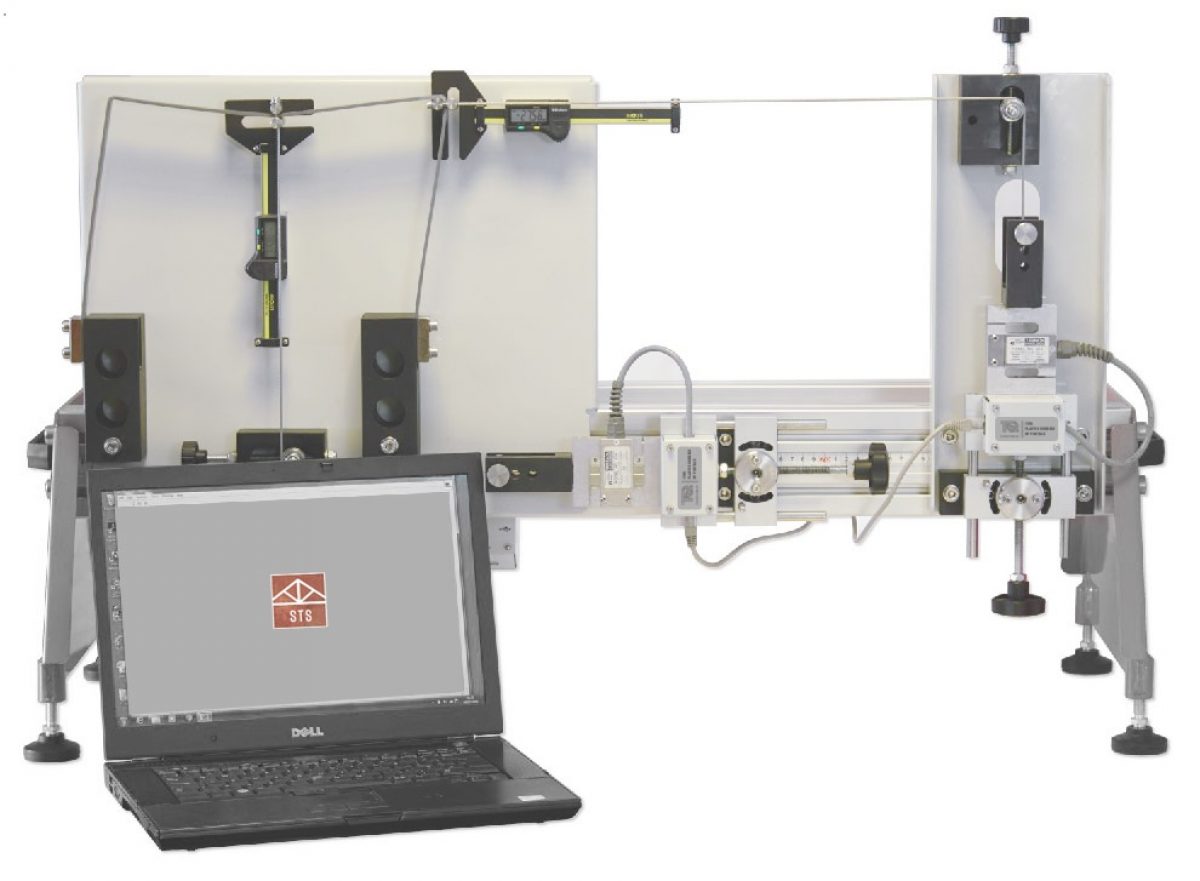

Euler Buckling of a Column (Next Generation Structures)

TecQuipment's Euler Buckling of a Column (STS12) is an experiment for the study of buckling of struts and the relationships between length, end fixing conditions and buckling load. Mounts on the Structures platform and connects to the Structures automatic data acquisition unit and software. This is one of the 21 apparatuses available in TQ's Next Generation Structures engineering lab experiments.