Complete Structures

The complete set of Structures includes seven kits to teach students the commonly taught principles of Structures across college and universities worldwide, in the subject area of mechical engineering ...

The main workstation is built of rugged steel and has a built-in panel that allows you to clip on the required component easily. Two water tanks with a combined capacity of 3L and inbuilt connectors allow students to set up each experiment quickly. When in storage, the flow pipes drop down into the frame, all components are stored within, the drip tray doubles as a back panel to enhance protection.

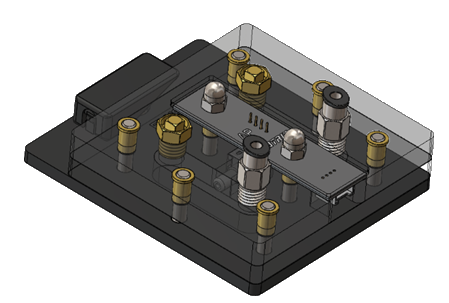

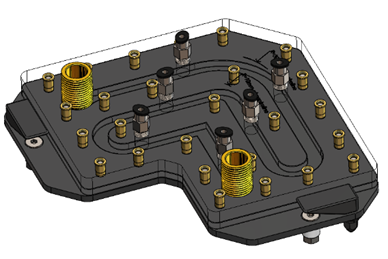

Working with a PC connection, the control box is the brain of the apparatus. Allowing simultaneous control of 2 pumps, while taking readings from 2 flow and 2 pressure sensors, the LCD screen gives students an instantaneous readout. The readings are passed from the control box, into the PC software, which plots results for student analysis, the data can also be logged for further interrogation by students.

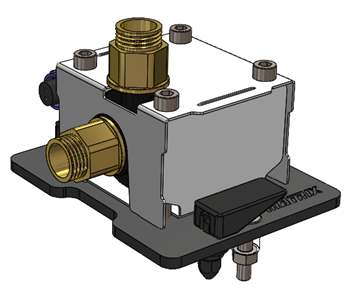

The Pump module has an operating voltage of 6-24v and produces a free-flow flow rate of 13/min. It works alongside the control box, to pump water around the apparatus. It features brass connection points for increased longevity.

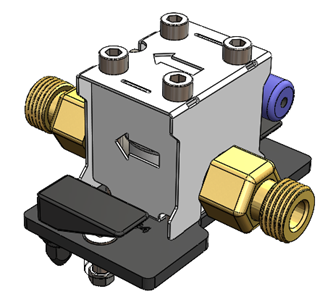

The Differential pressure sensor module is used to measure pressure in the fluid circuits; it features:

The Flow sensor module houses a calibrated turbine flow sensor, it is used to provide flow rate readout in the app and on the control module screen. It can measure 0-30l/min.

It has robust brass fittings for repeated assembly/disassembly.

The Bourdon gauge calibration module compares a known dead weight acting through a piston/cylinder of known diameter with the reading on the Bourdon gauge. The gauge is capable of measuring from 0-30 PSI.

The apparatus determines the accuracy and highlights the limitations of this type of pressure measurement device.

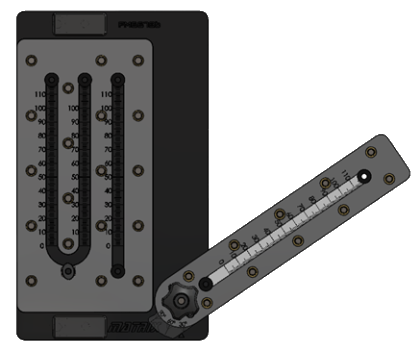

The multitube manometer has a measurement range of 0-120mm water and 4mm tubing using self-sealing push-in fittings.

The top of each limb is connected to the same air chamber at the top, so a reference pressure different from ambient can be applied. This is achieved by attaching a syringe with scroll wheel adjustment to the top port.

The U-tube and inclined manometer has a measurement range of 0-110mm.

4mm tubing is attached to the pressure ports using easy-to-use push-in fittings. The inclined manometer indexes to positions at 30°,60° and 90° from horizontal.

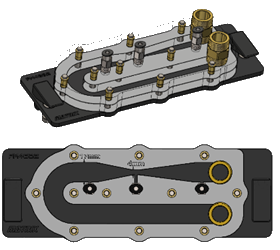

The losses in bends module consists of a visible fluid path with 3 different 90° bend geometries.

Each bend has self-sealing pressure ports before and after each bend so the pressure drop can be measured using the multitube manometer module.

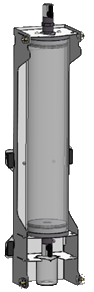

The viscosity apparatus consists of a 100mm diameter clear acrylic tube filled with vegetable glycerine. This assembly is housed in a sturdy metal enclosure that protects it while in storage or transported. It features ¼-turn valves at the top and bottom to release and retrieve spherical samples used in the experiment. The experiment demonstrates Stoke’s law. Students determine the viscosity of the glycerine by measuring the terminal velocity of spherical samples through the fluid.

The Centre of pressure module determines the center of pressure of partially and fully submerged surfaces. This experiment is carried out manually by students who can take readings and plot them within the curriculum for analysis.

The Venturi tube module is used to investigate Bernoulli’s principle. The flow section is constricted resulting in a pressure drop. Pressure ports at the widest and narrowest section permit attaching the differential pressure sensor for automated readings or the manometer module can be attached to enable manual readings.

Matrix products are easily packed away and stored in a classroom environment. The Fluids kit is no different and all 16 components, along with any accessories, are attached to and stored within the workstation.

Each component clips to the frame within the workstation and rugged plastic trays attach to the front and back of the unit for protection.

The flow pipes drop down into the workstation with the largest component, the viscosity apparatus attaching to the top of the unit.

The complete set of Structures includes seven kits to teach students the commonly taught principles of Structures across college and universities worldwide, in the subject area of mechical engineering ...